BUSINESS

Material Matters: Selecting the Right Resources for Your CNC Parts

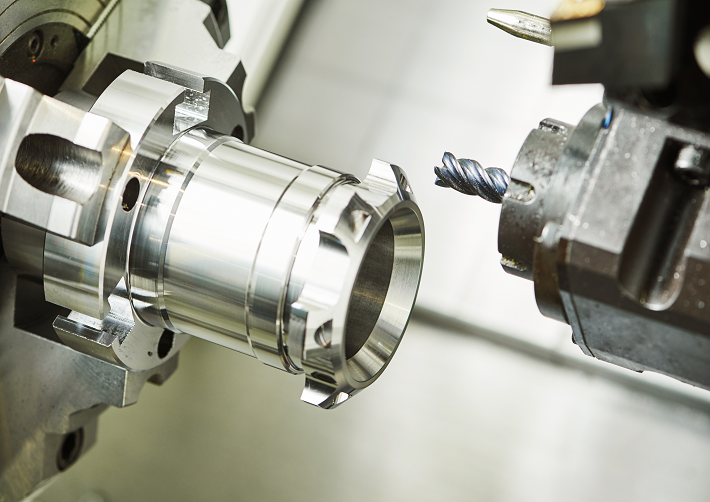

In terms of precision component manufacture, CNC (Computer Numerical Control) machining is the pinnacle of efficiency and accuracy. This cutting-edge method has transformed industries, allowing for the fabrication of complicated parts with unprecedented precision. However, every faultless CNC item is the result of an important decision: material selection. Indeed, material plays an important role in CNC machining, influencing not only part performance but also durability, cost-effectiveness, and overall quality.

In this post, we will look at the importance of material selection in CNC machining, including critical factors and guiding principles for manufacturers when selecting the correct resources.

Understanding CNC Machining Technique

Before getting into material selection, it’s important to understand the principles of CNC machining. CNC machining, as opposed to traditional machining methods that rely on manual operation, uses computer-controlled automated tools. This automation enables the exact and repeatable manufacture of complicated geometries, making it vital in a variety of industries, including aerospace, automotive, electronics, and medicine.

CNC machining often begins with a digital 3D model of the intended product, which is then converted into CNC machine instructions (G-codes). These instructions direct the movement of the cutting tools across the chosen material, molding it into the finished result. Beyond traditional components, the integration of CNC parts into customized injection molding processes allows for even greater precision and customization. CNC machines may perform a wide range of machining operations, including milling, turning, drilling, and grinding, to meet a variety of production requirements.

The Significance of Material Selection

The material used has a significant impact on the performance and attributes of the finished product, showcasing the unrivaled versatility and precision of the CNC machining technique. Manufacturers must carefully consider a variety of aspects when selecting the best material for their CNC parts, including metals, plastics, composites, and ceramics. Key considerations include:

Material qualities

Different applications require material qualities such as strength, hardness, elasticity, and thermal conductivity. For example, aeronautical components may demand lightweight yet durable materials such as aluminum or titanium, whereas automobile parts may prioritize rigidity and impact resistance. The properties of the material play an important role in guaranteeing longevity and maximum performance. For example, to avoid overheating and signal deterioration, circuit boards require materials with exceptional electrical conductivity and heat dissipation capabilities. Due to its semiconductor qualities, silicon is still an essential element in microelectronics, allowing for the complex circuitry of transistors and diodes. Furthermore, a new era of materials engineering has been brought about by advances in nanotechnology. Here, materials such as graphene and nanocomposites offer unmatched strength, conductivity, and flexibility, completely changing the way that electrical devices are made.

Machinability

Not all materials are equal in terms of their ability to be cut, drilled, or molded during CNC machining process. Machinability is influenced by factors such as hardness, toughness, and thermal conductivity, with softer materials like aluminum and brass often being easier to machine than hardened steels or exotic alloys. Moreover, machinability factors go beyond just cutting simplicity. Important considerations are surface polish and dimensional accuracy, especially in precision engineering applications such as medical devices and aircraft. Softer materials may be more tolerant of machining errors, but if not treated carefully, they may distort and develop surface irregularities. Harder materials, on the other hand, might need specific tooling and cutting methods to obtain the required precision without reducing tool life or jeopardizing the integrity of the finished component. Optimizing manufacturing processes and guaranteeing the quality of the final product entail striking a balance between machinability and the unique needs of the application.

Cost

Material costs have a substantial impact on manufacturing economics, influencing overall production costs and part affordability. While some materials may provide better performance, they are often more expensive. Balancing performance needs and economic considerations is critical for optimizing manufacturing budgets. Furthermore, a variety of factors, including availability, market demand, and geopolitical developments, might affect the cost of materials. Price changes can have a big effect on profit margins and competitiveness for businesses that depend heavily on large amounts of raw materials. Consequently, to reduce cost volatility and uphold quality standards, manufacturers frequently look for substitute materials or sources. It is also necessary to take into account the total cost of ownership, which includes not only the original cost of materials but also expenses related to processing, finishing, and upkeep over the product’s lifespan. Manufacturers can maximize value without sacrificing quality or performance by carefully weighing material selections and the expenses associated with them.

Surface Finish and Tolerances

The material used should be capable of producing the desired surface finish and dimensional tolerances for the part. Some materials may have better surface finish qualities, which allow for smoother surfaces and tighter tolerances without requiring extensive post-processing. The simplicity and viability of attaining particular surface finishes and tolerances can be greatly impacted by the material selection. For example, materials with good machinability and low effort requirements for exact surface finishes include stainless steel and some polymers. However, it may be difficult to achieve tight tolerances and the appropriate surface finishes when working with extremely abrasive materials or those that are prone to warping during milling. Dimensional stability over time can also be impacted by the material’s stability in various environmental settings, such as temperature and humidity. Therefore, it is essential to choose a material that complies with the required dimensional tolerances and surface finish criteria to achieve quality standards and guarantee the finished product’s operation.

Environmental Factors

Environmental considerations include corrosion resistance, chemical stability, and temperature resistance, which are especially important for parts that operate in harsh or demanding environments. Choosing materials that can withstand environmental conditions improves the durability and dependability of CNC components.

Environmental aspects also include sustainability issues, which motivate the use of environmentally friendly materials and production techniques. Choosing materials with the least possible environmental impact and supporting recycling and reuse programs are crucial at a time when environmental responsibility is becoming more and more important. In addition to lessening their influence on the environment, sustainable materials also support business sustainability objectives and consumer preferences for eco-friendly goods. Manufacturers can enhance their competitiveness by giving priority to materials with excellent environmental performance and help the global movement towards a more sustainable future.

Common Materials Used in CNC Machining

While the selection of materials for CNC machining is extensive, a few standouts dominate the production landscape:

Metals

Aluminum, steel, stainless steel, titanium, and copper are commonly used in CNC machining due to their good mechanical qualities, thermal conductivity, and durability. Aluminum alloys, in particular, are valued for their lightweight yet strong properties, making them perfect for aerospace, automotive, and consumer electronics applications. When it comes to CNC machining, metals are versatile since each type has special qualities that make them suitable for certain uses. Steel is widely used in structural parts for infrastructure and machinery because of its great strength and durability. Since stainless steel doesn’t corrode, it’s the perfect material for parts that are exposed to hostile environments, such as chemical processing or marine equipment. Titanium is preferred in the sporting goods, medical, and aerospace industries due to its remarkable strength-to-weight ratio and biocompatibility. Copper is prized in heat exchangers and plumbing fittings due to its great electrical conductivity, which makes it essential for electrical and electronic components. CNC producers can customize the material selection to meet unique application demands and performance criteria because of the variety of metal possibilities available.

Plastics

Plastics are versatile, affordable, and easy to machine, making them ideal for a wide range of CNC parts. Acrylic, polycarbonate, ABS (Acrylonitrile Butadiene Styrene), and nylon are popular materials with qualities such as transparency, impact resistance, and chemical stability. Plastics satisfy a wide range of functional and aesthetic needs and provide an abundance of possibilities for CNC machining. Acrylic is used in signage, exhibition cases, and architectural features. It is valued for its optical clarity and weather resistance. Because of its reputation for impact resistance and transparency, polycarbonate is used extensively in electronic enclosures, safety equipment, and automobile parts. Preferred for its robustness, stiffness, and simplicity in post-processing, ABS finds widespread application in consumer items, automobile interiors, and prototyping. Given its durability, low coefficient of friction, and chemical resistance, nylon is an essential material for gears, bearings, and structural parts. Plastics can be machined precisely and consistently to create complicated parts for a variety of sectors. This gives producers flexibility in choosing materials to fulfill a range of design criteria.

Composites

These are materials that combine the strength and stiffness of fibers with the versatility of polymers. Examples include carbon fiber-reinforced polymers (CFRP) and fiberglass-reinforced polymers. These materials find use in the aerospace, automotive, and sporting goods industries, where lightweight and high strength-to-weight ratios are important. Given their special combination of qualities, composites are becoming more and more common in CNC machining applications. Because of their remarkable strength-to-weight ratios, carbon fiber-reinforced polymers (CFRP) and fiberglass-reinforced polymers are perfect for parts where weight reduction is crucial, like airplane fuselages, car body panels, and high-performance sports equipment. Depending on the demands of a given application, designers can optimize strength, stiffness, and impact resistance thanks to the directed alignment of fibers inside the matrix, which enables customizable mechanical properties.

Ceramics

Ceramics have outstanding hardness, wear resistance, and temperature stability, making them ideal for demanding applications in the aerospace, medical, and industrial fields. While ceramics are notoriously difficult to mill due to their brittle nature, modern CNC techniques and tools have made ceramic machining more viable. Furthermore, ceramics have outstanding thermal and electrical insulation qualities, which makes them invaluable for electrical insulation applications and high-temperature settings.

Ceramic materials with high abrasion resistance and chemical inertness, such as silicon carbide and aluminum oxide, are frequently employed in cutting tools, wear-resistant components, and chemical processing equipment. To overcome the difficulties involved with ceramic machining, sophisticated techniques like ultrasonic and laser-assisted machining have been developed. These techniques allow for the fabrication of exact features and complex shapes with the least amount of tool wear. Ceramics remain the material of choice for CNC machining in critical applications where performance is crucial since industries seek materials that can survive harsh environments while retaining dimensional stability and reliability.

Exotic Alloys

Inconel, Monel, and Hastelloy are used in specific applications that require high-performance characteristics. These high-performance materials provide improved corrosion resistance, high-temperature strength, and outstanding mechanical qualities, but at a higher cost and machining complexity. Their extensive use goes beyond conventional industrial environments, as cutting-edge technologies take advantage of their special qualities to provide creative solutions. More and more, Inconel, Monel, and Hastelloy are being used in cutting-edge industries like renewable energy, where their ability to withstand extreme conditions is essential for parts like solar panels, wind turbines, and hydrogen fuel cells. Furthermore, the development of additive printing techniques has created new opportunities for the optimization and customisation of these unusual alloys, allowing complex designs with improved performance characteristics to be created. Because of these unusual alloys’ adaptability and dependability, research and development efforts to push the boundaries of material science will continue, and their significance in forming future technologies will be long-lasting.

Conclusion

In the field of CNC machining, material selection is essential in influencing the performance, quality, and cost-effectiveness of manufactured parts. Manufacturers can optimize the production process and produce greater results by understanding the distinct qualities and requirements of different materials. Whether it’s balancing strength and weight in aircraft components or maximizing cost-effectiveness in consumer electronics, using the correct materials ensures that CNC parts satisfy the highest precision and reliability standards. As technology and material science develop, the search for the ideal material for CNC machining continues, fueling innovation and pushing the limits of manufacturing excellence.

BUSINESS

The Smart Canadian’s Guide to Lowering Insurance Costs

Insurance is a necessity for peace of mind, but it can also make a significant dent in your budget. Whether it’s auto, home, or life insurance, your premiums can add up quickly. But here’s the bright side: there are effective ways to minimize your insurance costs without sacrificing coverage. Find expert Canadian insurance solutions with Sharp Insurance to get started on smarter savings today.

This guide is designed to help Canadians take control of their insurance expenses. By understanding how insurance pricing works and adopting a few smart strategies, you can save hundreds (or more) annually.

Shop Around and Compare Quotes

One of the simplest yet most overlooked strategies for lowering your insurance costs is shopping around. Not all insurance providers are created equal, and their pricing structures can vary significantly based on your profile, location, and coverage needs.

Use Online Comparison Tools

Websites like Ratehub or LowestRates.ca make it easier than ever to compare insurance premiums from multiple providers. These tools allow you to input your details once and receive a variety of personalized quotes. This quick process can reveal savings opportunities you may never have guessed existed.

Get Quotes from Multiple Providers

Don’t just stop at online tools. Contact insurance providers directly and ask for quotes. Some insurers may offer loyalty discounts or exclusive deals for prospective customers who inquire directly. Make sure to compare the coverage, not just the price, to ensure you’re getting the best value.

Pro Tip

Check reviews and rating platforms like the Better Business Bureau to ensure the provider not only offers competitive rates but also great service.

Increase Your Deductible

A deductible is the amount you agree to pay out-of-pocket before your insurance kicks in to cover the rest. Increasing your deductible can reduce your premium, sometimes significantly.

How Deductibles Work

For example, if you opt for a $1,000 deductible instead of $500, your monthly or annual premium will often decrease. Why? Because you’re agreeing to take on a higher portion of the risk.

Weighing the Pros and Cons

While opting for a higher deductible lowers your premium, it’s crucial to ensure that you have enough emergency savings in case you need to pay that deductible.

Consider this:

- Pros: Lower monthly premiums, potential long-term savings.

- Cons: Higher upfront costs in case of an incident.

Evaluate your financial situation and risk tolerance before increasing your deductible.

Bundle Your Insurance Policies

Bundling your insurance policies—such as auto, home, and life insurance—with the same provider is another excellent way to save. Many insurers offer discounts when you consolidate multiple policies with them.

Benefits of Bundling

- Combined discounts: Bundling can save you up to 25% on your premiums.

- Simplified management: Dealing with one provider is more convenient than juggling multiple policies from different companies.

- Extra perks: Some insurers offer enhanced customer service or loyalty rewards for bundled policies.

How to Find the Best Bundling Deals

Start by asking your current providers about bundling options. Then compare their offers with competitors to ensure you’re receiving the maximum discount. Remember to confirm that you’re not losing any important coverages in the process of bundling.

Improve Your Credit Score

Did you know that your credit score can impact your insurance premiums in Canada? Insurers often use your credit score as an indicator of how “risky” you might be to insure. The better your score, the lower your premiums may be.

The Connection Between Credit Scores and Insurance Rates

Insurance companies view individuals with higher credit scores as more responsible and less likely to file frequent claims. While not all provinces allow the use of credit score assessments (Quebec and Newfoundland and Labrador, for example, restrict this practice), in most provinces, keeping a good credit score is advantageous.

Tips for Improving Your Credit Score

- Pay bills on time: Late payments negatively affect your score.

- Keep your credit utilization low: Aim to use less than 30% of your credit limit.

- Monitor your credit report: Check for errors or inaccuracies that could be dragging down your score.

Improving your credit score takes time, but the financial benefits go beyond insurance savings, impacting other areas of your financial life as well.

Take Advantage of Discounts

Many insurance providers offer a variety of discounts that customers aren’t often aware of. By knowing what to look for, you may unlock significant savings.

Available Discounts

- Student discounts: Young drivers in school can access reduced auto insurance rates.

- Senior discounts: Retirees and seniors typically qualify for discounts on auto and home insurance.

- Professional discounts: Belong to a union or professional organization? You might be eligible for specific group discounts.

How to Inquire About and Apply for Discounts

Be proactive! Call your insurance provider and ask for a full breakdown of discounts you qualify for. Additionally, ensure you’ve provided up-to-date details about your current circumstances, as this can often reveal overlooked savings opportunities.

Pro Tip

Participate in telematics programs if your auto insurer offers them. These programs track your driving habits and may reward you with lower rates for safe driving.

Taking Control of Your Insurance Costs

Finding ways to reduce your insurance expenses doesn’t have to be complicated. By shopping around, reevaluating your deductible, bundling policies, improving your credit score, and taking advantage of discounts, you can enjoy significant savings while maintaining excellent coverage.

Remember that being proactive and informed is key to success. Set a reminder each year to review your insurance policies and explore opportunities for additional savings.

At the end of the day, every dollar saved on insurance is a dollar you can invest elsewhere in your future. Take control of your coverage today and ensure your hard-earned money is working as efficiently as possible.

BUSINESS

When To Call for AC Repair vs. Regular Maintenance

Most problems of an air conditioning system may seem minor at first, but can evolve into more severe disruptions when left unresolved. Preventive maintenance is a service to keep the system in working condition through regular checkups. Repair is needed when the unit exhibits signs of mechanical or electrical failure. Here is when to schedule for AC repair versus regular maintenance:

Temperature Variations

Restricted airflow, failing motors, or internal refrigerant imbalances often cause uneven cooling. Although maintenance clears surface-level buildup and aids airflow, persistent temperature variation in different rooms may indicate faulty internal controls or deteriorated circulation systems. The parts responsible for distributing air evenly might have become misaligned or are no longer working correctly. Such fluctuations often persist as performance regulators within the system start to fail. When this happens, a professional may need to replace a part. When such symptoms occur, professional AC repair helps to detect underlying faults, recalibrate settings, or replace worn-out components.

Persistent Airflow Issues

Even after a system has undergone routine maintenance, airflow issues may still be present. Decreased airflow may occur due to electrical irregularities affecting the blowers’ functioning, pressure imbalances, or deteriorating fan performance. Although regular service may involve cleaning and filter replacement, airflow limitations due to internal damage or system wear may go unaddressed. These conditions may worsen when the blower assembly becomes weak, resulting in the unit having less capacity to force air through the vents. Air passage can also be disrupted by disconnected or damaged internal seals, which lowers overall efficiency. A professional will diagnose and repair the issue.

Unusual Cycling Behavior

Cooling systems should cycle at a normal rate. Internal sensors or electrical control elements may be compromised when they are turned on and off too often. Alternatively, when a unit fails to cycle off, the root cause may be temperature control errors or a cooling load imbalance. Short cycling and long operation wear the system. Relays and communication boards that control these cycles may lose calibration or deteriorate over time. Professional repair is necessary to diagnose and address the underlying cause, avoiding further degradation and restoring proper cycling functionality.

Unusual Noises

The noise from the unit may increase as internal parts wear out or become misaligned. Rattling is usually an indication of loose mechanical components, and buzzing sounds may occur due to power fluctuations or faulty electrical components. Maintenance may involve general inspection or oil application, but not opening assemblies or replacing damaged parts. When such noises are repeated, subsequent use of the system may cause further internal damage. This is when you should get targeted mechanical repair to promote smooth operation and avoid cascading system failure.

Drainage Problems and Moisture Accumulation

The presence of moisture around the air conditioning unit may indicate drainage failure. A blocked condensate drain line is a common reason, as it prevents water from leaving the system. Dust, algae, and debris can accumulate over time within the line, eventually forming a clog that causes water to pool around the unit. When a drip pan cracks or shifts out of position, it cannot collect and channel condensation properly, leading to pooling.

If the evaporator coil freezes and thaws due to internal components, the drainage system can be overwhelmed by excess water. These problems go beyond routine servicing and require corrective action to restore proper moisture management. Repairs must aim to clear blocked drains, seal or replace broken parts, and restore system balances to prevent permanent damage and enhance reliability.

Hire an AC Repair Company

Although routine maintenance helps to maintain functionality and efficiency, it has its limits. Repair is required when performance is disrupted by mechanical, electrical, or control-based faults. Select an experienced provider in both routine maintenance and targeted repairs. An experienced team will not only keep the system clean and calibrated but will also identify when deeper intervention is required. Hire an AC repair company to access timely interventions and expert solutions.

BUSINESS

Innovative Strategies For Building A Personal Brand Online

Why Personal Branding Matters In The Digital Era

Personal branding has become a necessity in today’s digital world, with over 70% of employers and collaborators searching for individuals online before making hiring or partnership decisions. A thoughtful and intentional brand presence can make professionals recognized, trusted, and remembered. Trailblazers like Bradley Bakotic demonstrate how authenticity and strategy can create a resonating personal brand. A recognizable digital presence is about communicating your mission, values, and expertise to a broad audience, building relationships, inspiring others, and leaving a meaningful impact in your field. A personal brand built on substance and sincerity helps people remember your name and associate you with trust and reliability.

Core Elements Of An Effective Online Identity

An effective online identity requires clarity on your core message and a consistent profile across all relevant platforms, such as LinkedIn, Twitter, and personal websites. It includes a consistent headshot, a unified username, and a value-focused tagline. Authenticity sets strong personal brands apart, as sharing real stories, passions, or behind-the-scenes insights helps break down barriers and foster trust. Being candid about your journey, including its challenges and growth moments, can resonate with your audience. Honesty, combined with a visually uniform digital footprint, creates immediate recognition and drives loyalty over time. People are drawn to people, not just credentials or job titles.

How To Use Social Channels Intentionally

- Choose platforms with purpose: Focus your efforts on the platforms that your target audience frequents most. For instance, LinkedIn remains the go-to hub for professionals, while Instagram and TikTok excel for those in the creative or lifestyle spaces.

- Engage meaningfully: Don’t just broadcast—join the conversation. Make it a habit to reply to comments, share perspectives in group threads, and participate in online events or Q&As.

- Stay consistent yet flexible: Develop a regular posting schedule and remain adaptable. The audience needs to shift; be ready to experiment with content forms—such as stories, video snippets, and polls—to see what sparks the most engagement.

A targeted approach to social media can yield greater returns as it fosters trust, collaboration, and advocacy. Analytics can help identify which content and timing align with the community’s interests, ensuring that your efforts are always aligned with the community’s interests.

The Role Of Storytelling & Thought Leadership

Memorable brands are built on compelling stories that capture emotional connections through both success and failure. Audiences seek transparent, open, and passionate voices about progress. Personal anecdotes about career paths, pivots, and lessons learned foster empathy. The best brands position themselves as trusted experts by sharing unique opinions and insights on industry trends. Authentic stories and thoughtful commentary are viewed as leaders within their fields. Real-world impact is achieved when storytelling and thought leadership are combined, allowing expertise and humanity to shine.

Strategic Content Creation For Maximum Engagement

- Pinpoint your audience’s questions: Identify community challenges and pain points to provide actionable content that enhances professional or personal growth, as attention spans are short.

- Pack posts with actionable value: Create a variety of content formats, including how-to guides, tutorials, infographics, and video explainers, to simplify complex topics and demonstrate your expertise and willingness to empower others.

- Recycle and customize content: One great post can reach new audiences, such as a tweet thread, an email newsletter, or even a short video. Repurposing ensures your message is heard on multiple platforms while respecting the unique consumption habits of each audience segment.

Forbes highlights that compelling, story-driven content outperforms promotional posts on social channels, as it encourages participation, addresses real-world questions, and inspires responses, thereby boosting awareness and engagement.

Measuring Impact And Adapting Your Brand

An effective personal brand matures through continuous monitoring and adaptation. Utilize analytics tools to observe engagement rates, follower growth, and demographics. Look for patterns in post-reception, such as specific times or global events. Be agile and experiment with new content themes or formats based on user feedback. Pay attention to the quality of engagement, including the frequency of questions, sharing, and opportunities. For interaction, it helps refine your message and deepen digital relationships.

Emerging Trends In Personal Branding

Personal branding must adapt to rapidly changing digital trends, such as short-form video formats like Instagram Reels, TikTok videos, and YouTube Shorts, which effectively capture attention and foster deeper connections with audiences. Integrating interactive elements, such as Q&A sessions or live streams, can further enhance brand engagement and interaction. The responsible use of AI for content ideation and optimization is crucial, but transparency and accessibility are equally essential. Staying updated on algorithm changes, new content formats, and digital etiquette ensures a fresh, relevant, and impactful brand.

Common Pitfalls And How To Avoid Them

- Over-promotion: Balance is crucial. While sharing achievements is fantastic, audiences quickly disengage from constant self-promotion. Deliver real, regular value through educational, relatable, and inspiring content.

- Lack of consistency: Irregular updates erode trust and recall. Create a manageable schedule and stick to it, even if it’s just once or twice per week.

- Failure to listen: Engagement is a two-way street. Make active listening part of your strategy—respond to comments, encourage feedback, and adapt readily to changes in your community’s needs.

- Overexposure: Striking a balance between personal sharing and privacy is vital. Protect sensitive information and remember that being authentic doesn’t mean revealing every detail.

Maintaining a healthy and impactful brand presence requires awareness of common missteps, staying tuned to followers, adapting to changing digital norms, and communicating with clarity and heart.

-

GENERAL2 years ago

GENERAL2 years agoDiscovering the Artistic Brilliance of Derpixon: A Deep Dive into their Animation and Illustration

-

Posts2 years ago

Posts2 years agoSiegel, Cooper & Co.

-

FASHION2 years ago

FASHION2 years agoThe Many Faces of “λιβαισ”: A Comprehensive Guide to its Symbolism in Different Cultures

-

Lifestyle2 years ago

Lifestyle2 years agoPurenudism.com: Unveiling the Beauty of Naturist Lifestyle

-

Lifestyle2 years ago

Lifestyle2 years agoBaddieHub: Unleashing Confidence and Style in the Ultimate Gathering Spot for the Baddie Lifestyle

-

HEALTH1 year ago

HEALTH1 year agoTransformative Health Solutions: Unveiling the Breakthroughs of 10x Health

-

Entertainment2 years ago

Entertainment2 years agoGeekzilla Podcast: Navigating the World of Pop Culture, Gaming, and Tech

-

Lifestyle11 months ago

Lifestyle11 months agoSandra orlow: Unraveling the Story of an Iconic Figure