BUSINESS

Material Matters: Selecting the Right Resources for Your CNC Parts

In terms of precision component manufacture, CNC (Computer Numerical Control) machining is the pinnacle of efficiency and accuracy. This cutting-edge method has transformed industries, allowing for the fabrication of complicated parts with unprecedented precision. However, every faultless CNC item is the result of an important decision: material selection. Indeed, material plays an important role in CNC machining, influencing not only part performance but also durability, cost-effectiveness, and overall quality.

In this post, we will look at the importance of material selection in CNC machining, including critical factors and guiding principles for manufacturers when selecting the correct resources.

Understanding CNC Machining Technique

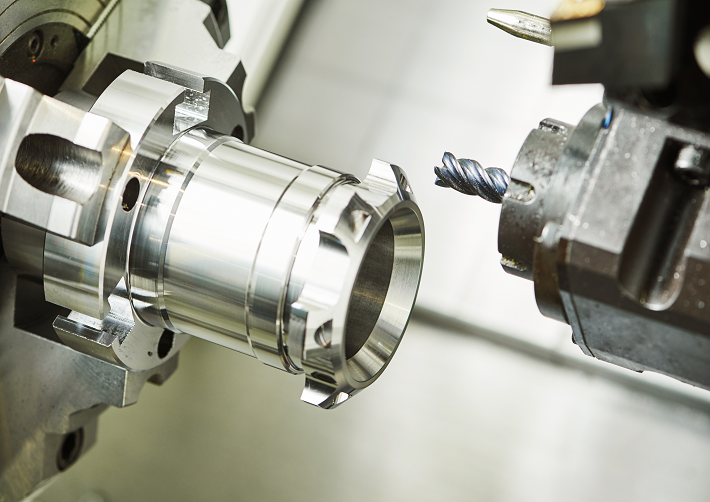

Before getting into material selection, it’s important to understand the principles of CNC machining. CNC machining, as opposed to traditional machining methods that rely on manual operation, uses computer-controlled automated tools. This automation enables the exact and repeatable manufacture of complicated geometries, making it vital in a variety of industries, including aerospace, automotive, electronics, and medicine.

CNC machining often begins with a digital 3D model of the intended product, which is then converted into CNC machine instructions (G-codes). These instructions direct the movement of the cutting tools across the chosen material, molding it into the finished result. Beyond traditional components, the integration of CNC parts into customized injection molding processes allows for even greater precision and customization. CNC machines may perform a wide range of machining operations, including milling, turning, drilling, and grinding, to meet a variety of production requirements.

The Significance of Material Selection

The material used has a significant impact on the performance and attributes of the finished product, showcasing the unrivaled versatility and precision of the CNC machining technique. Manufacturers must carefully consider a variety of aspects when selecting the best material for their CNC parts, including metals, plastics, composites, and ceramics. Key considerations include:

Material qualities

Different applications require material qualities such as strength, hardness, elasticity, and thermal conductivity. For example, aeronautical components may demand lightweight yet durable materials such as aluminum or titanium, whereas automobile parts may prioritize rigidity and impact resistance. The properties of the material play an important role in guaranteeing longevity and maximum performance. For example, to avoid overheating and signal deterioration, circuit boards require materials with exceptional electrical conductivity and heat dissipation capabilities. Due to its semiconductor qualities, silicon is still an essential element in microelectronics, allowing for the complex circuitry of transistors and diodes. Furthermore, a new era of materials engineering has been brought about by advances in nanotechnology. Here, materials such as graphene and nanocomposites offer unmatched strength, conductivity, and flexibility, completely changing the way that electrical devices are made.

Machinability

Not all materials are equal in terms of their ability to be cut, drilled, or molded during CNC machining process. Machinability is influenced by factors such as hardness, toughness, and thermal conductivity, with softer materials like aluminum and brass often being easier to machine than hardened steels or exotic alloys. Moreover, machinability factors go beyond just cutting simplicity. Important considerations are surface polish and dimensional accuracy, especially in precision engineering applications such as medical devices and aircraft. Softer materials may be more tolerant of machining errors, but if not treated carefully, they may distort and develop surface irregularities. Harder materials, on the other hand, might need specific tooling and cutting methods to obtain the required precision without reducing tool life or jeopardizing the integrity of the finished component. Optimizing manufacturing processes and guaranteeing the quality of the final product entail striking a balance between machinability and the unique needs of the application.

Cost

Material costs have a substantial impact on manufacturing economics, influencing overall production costs and part affordability. While some materials may provide better performance, they are often more expensive. Balancing performance needs and economic considerations is critical for optimizing manufacturing budgets. Furthermore, a variety of factors, including availability, market demand, and geopolitical developments, might affect the cost of materials. Price changes can have a big effect on profit margins and competitiveness for businesses that depend heavily on large amounts of raw materials. Consequently, to reduce cost volatility and uphold quality standards, manufacturers frequently look for substitute materials or sources. It is also necessary to take into account the total cost of ownership, which includes not only the original cost of materials but also expenses related to processing, finishing, and upkeep over the product’s lifespan. Manufacturers can maximize value without sacrificing quality or performance by carefully weighing material selections and the expenses associated with them.

Surface Finish and Tolerances

The material used should be capable of producing the desired surface finish and dimensional tolerances for the part. Some materials may have better surface finish qualities, which allow for smoother surfaces and tighter tolerances without requiring extensive post-processing. The simplicity and viability of attaining particular surface finishes and tolerances can be greatly impacted by the material selection. For example, materials with good machinability and low effort requirements for exact surface finishes include stainless steel and some polymers. However, it may be difficult to achieve tight tolerances and the appropriate surface finishes when working with extremely abrasive materials or those that are prone to warping during milling. Dimensional stability over time can also be impacted by the material’s stability in various environmental settings, such as temperature and humidity. Therefore, it is essential to choose a material that complies with the required dimensional tolerances and surface finish criteria to achieve quality standards and guarantee the finished product’s operation.

Environmental Factors

Environmental considerations include corrosion resistance, chemical stability, and temperature resistance, which are especially important for parts that operate in harsh or demanding environments. Choosing materials that can withstand environmental conditions improves the durability and dependability of CNC components.

Environmental aspects also include sustainability issues, which motivate the use of environmentally friendly materials and production techniques. Choosing materials with the least possible environmental impact and supporting recycling and reuse programs are crucial at a time when environmental responsibility is becoming more and more important. In addition to lessening their influence on the environment, sustainable materials also support business sustainability objectives and consumer preferences for eco-friendly goods. Manufacturers can enhance their competitiveness by giving priority to materials with excellent environmental performance and help the global movement towards a more sustainable future.

Common Materials Used in CNC Machining

While the selection of materials for CNC machining is extensive, a few standouts dominate the production landscape:

Metals

Aluminum, steel, stainless steel, titanium, and copper are commonly used in CNC machining due to their good mechanical qualities, thermal conductivity, and durability. Aluminum alloys, in particular, are valued for their lightweight yet strong properties, making them perfect for aerospace, automotive, and consumer electronics applications. When it comes to CNC machining, metals are versatile since each type has special qualities that make them suitable for certain uses. Steel is widely used in structural parts for infrastructure and machinery because of its great strength and durability. Since stainless steel doesn’t corrode, it’s the perfect material for parts that are exposed to hostile environments, such as chemical processing or marine equipment. Titanium is preferred in the sporting goods, medical, and aerospace industries due to its remarkable strength-to-weight ratio and biocompatibility. Copper is prized in heat exchangers and plumbing fittings due to its great electrical conductivity, which makes it essential for electrical and electronic components. CNC producers can customize the material selection to meet unique application demands and performance criteria because of the variety of metal possibilities available.

Plastics

Plastics are versatile, affordable, and easy to machine, making them ideal for a wide range of CNC parts. Acrylic, polycarbonate, ABS (Acrylonitrile Butadiene Styrene), and nylon are popular materials with qualities such as transparency, impact resistance, and chemical stability. Plastics satisfy a wide range of functional and aesthetic needs and provide an abundance of possibilities for CNC machining. Acrylic is used in signage, exhibition cases, and architectural features. It is valued for its optical clarity and weather resistance. Because of its reputation for impact resistance and transparency, polycarbonate is used extensively in electronic enclosures, safety equipment, and automobile parts. Preferred for its robustness, stiffness, and simplicity in post-processing, ABS finds widespread application in consumer items, automobile interiors, and prototyping. Given its durability, low coefficient of friction, and chemical resistance, nylon is an essential material for gears, bearings, and structural parts. Plastics can be machined precisely and consistently to create complicated parts for a variety of sectors. This gives producers flexibility in choosing materials to fulfill a range of design criteria.

Composites

These are materials that combine the strength and stiffness of fibers with the versatility of polymers. Examples include carbon fiber-reinforced polymers (CFRP) and fiberglass-reinforced polymers. These materials find use in the aerospace, automotive, and sporting goods industries, where lightweight and high strength-to-weight ratios are important. Given their special combination of qualities, composites are becoming more and more common in CNC machining applications. Because of their remarkable strength-to-weight ratios, carbon fiber-reinforced polymers (CFRP) and fiberglass-reinforced polymers are perfect for parts where weight reduction is crucial, like airplane fuselages, car body panels, and high-performance sports equipment. Depending on the demands of a given application, designers can optimize strength, stiffness, and impact resistance thanks to the directed alignment of fibers inside the matrix, which enables customizable mechanical properties.

Ceramics

Ceramics have outstanding hardness, wear resistance, and temperature stability, making them ideal for demanding applications in the aerospace, medical, and industrial fields. While ceramics are notoriously difficult to mill due to their brittle nature, modern CNC techniques and tools have made ceramic machining more viable. Furthermore, ceramics have outstanding thermal and electrical insulation qualities, which makes them invaluable for electrical insulation applications and high-temperature settings.

Ceramic materials with high abrasion resistance and chemical inertness, such as silicon carbide and aluminum oxide, are frequently employed in cutting tools, wear-resistant components, and chemical processing equipment. To overcome the difficulties involved with ceramic machining, sophisticated techniques like ultrasonic and laser-assisted machining have been developed. These techniques allow for the fabrication of exact features and complex shapes with the least amount of tool wear. Ceramics remain the material of choice for CNC machining in critical applications where performance is crucial since industries seek materials that can survive harsh environments while retaining dimensional stability and reliability.

Exotic Alloys

Inconel, Monel, and Hastelloy are used in specific applications that require high-performance characteristics. These high-performance materials provide improved corrosion resistance, high-temperature strength, and outstanding mechanical qualities, but at a higher cost and machining complexity. Their extensive use goes beyond conventional industrial environments, as cutting-edge technologies take advantage of their special qualities to provide creative solutions. More and more, Inconel, Monel, and Hastelloy are being used in cutting-edge industries like renewable energy, where their ability to withstand extreme conditions is essential for parts like solar panels, wind turbines, and hydrogen fuel cells. Furthermore, the development of additive printing techniques has created new opportunities for the optimization and customisation of these unusual alloys, allowing complex designs with improved performance characteristics to be created. Because of these unusual alloys’ adaptability and dependability, research and development efforts to push the boundaries of material science will continue, and their significance in forming future technologies will be long-lasting.

Conclusion

In the field of CNC machining, material selection is essential in influencing the performance, quality, and cost-effectiveness of manufactured parts. Manufacturers can optimize the production process and produce greater results by understanding the distinct qualities and requirements of different materials. Whether it’s balancing strength and weight in aircraft components or maximizing cost-effectiveness in consumer electronics, using the correct materials ensures that CNC parts satisfy the highest precision and reliability standards. As technology and material science develop, the search for the ideal material for CNC machining continues, fueling innovation and pushing the limits of manufacturing excellence.

BUSINESS

Lead Generation Packages for B2B Success

Companies deal with unpredictable pipelines more often than they’d like. One month looks great, the next one is quiet. That kind of inconsistency slows growth and makes forecasting tough. Lead generation packages solve this by providing businesses with a repeatable, structured system rather than scattered efforts. You get clarity on what’s being done, who’s being targeted, and when results should show up.

What’s Typically Included in B2B Lead Generation Packages

A solid package covers every step required to find and engage the right buyers. It keeps outreach unified, consistent, and tied to your Ideal Customer Profile.

- Prospect research & ICP refinement: This begins with defining the right prospects. A team reviews your ICP, analyzes markets, and builds targeted lists of decision-makers. The goal is to make sure outreach focuses on companies that actually match your offer.

- Multi-channel outreach (email, LinkedIn, calls): Reaching prospects through several channels increases response rates. Packages usually include coordinated outreach via email, LinkedIn, and phone, ensuring your message reaches prospects where they prefer to communicate.

- Messaging creation & personalization: Strong outreach depends on relevant, human-sounding messaging. Teams write email sequences, LinkedIn scripts, and calling guides tailored to your industry. Personalization is added to help you stand out from generic campaigns.

- Data validation, enrichment, and QA: Good data is at the core of predictable results. Every contact is checked, verified, and enriched to reduce bounce rates and avoid wasted outreach. Ongoing QA keeps campaigns clean and compliant.

Learn more about the key cost drivers behind lead generation services, how different package tiers influence overall spend, and what factors businesses should evaluate before choosing an option.

Types of Lead Gen Packages

Lead generation isn’t one-size-fits-all. Different companies have different levels of readiness, sales cycles, and goals, so packages are built to match those stages. Below are the three most common options, along with the types of businesses they’re designed for.

Pilot Package

A pilot package is the safest starting point for teams that want to test outbound without committing to a long-term plan. It’s ideal for companies that are exploring a new ICP, entering a fresh market, or simply unsure how well outbound will work for their offer.

This option usually runs for one to two months and focuses on a smaller volume of outreach. The goal is fast learning. You see which messaging resonates, which titles get the most replies, how long the sales cycle feels, and whether your product speaks to the prospects you’re targeting.

The pilot package works especially well for startups, companies launching new products, or B2B teams that have relied primarily on referrals and inbound and want to add outbound without risk.

Growth/Business Package

The business growth package is for companies that already know their ICP and want predictable monthly meetings. It’s built for teams that need stability: steady outreach, steady performance, and a precise monthly flow of qualified conversations.

This package usually includes larger volumes of research, multi-channel outreach, richer personalization, and ongoing optimization. It’s the sweet spot for most B2B companies.

Sales teams benefit the most here: SDRs get a reliable stream of leads instead of scrambling for prospects, and founders no longer rely on sporadic outreach. If your next step is scaling revenue, increasing deal flow, or shortening the gap between closed deals, this package is a strong fit.

Enterprise Package

Enterprise packages are built for companies with broad territories, complex buyer journeys, or aggressive growth goals. They’re designed for teams that need outbound running across multiple markets, industries, or product lines simultaneously.

These packages handle high outreach volumes, deeper levels of research, and custom workflows integrated with internal systems. They often include multiple SDRs, multilingual outreach, advanced reporting, and detailed performance tracking.

Enterprise fits companies with mature sales operations, larger teams, or VP-level growth targets where consistency, scale, and cross-market coverage are non-negotiable. It’s the best choice for organizations that treat outbound as a long-term engine rather than a temporary boost.

Key Factors to Consider When Choosing a Package

Choosing the right lead generation package comes down to understanding what your team needs today and what will matter in a few months. A package should match your goals, support your sales process, and give you the level of control you want over results. Here are the core factors to look at before committing to anything:

- Monthly lead/meeting volume: Ensure it aligns with your sales capacity. Too few meetings slow growth, but too many can overwhelm a small team. The right package fits your bandwidth and revenue targets.

- Channel mix: Effective outbound uses multiple channels. Packages that combine email, LinkedIn, and phone outreach usually bring stronger response rates. Check if the provider adapts the mix to your audience.

- Quality of data and research standards: Strong results depend on accurate contact data. Look for manual research, verification steps, and clear QA practices. Poor data leads to bounces, low reply rates, and wasted time.

- Industry-specific expertise: If your market is niche or technical, the team running your outreach should understand it. Familiarity with your industry improves messaging, targeting, and overall performance.

When these factors align, a lead generation package becomes a reliable growth engine rather than an experiment.

Conclusion

Structured packages give companies a clear path to steady growth. Instead of chasing inconsistent outreach or guessing what to try next, you get a system that delivers qualified conversations every month. The research, messaging, outreach, and reporting all work together, making results easier to track and improve.

BUSINESS

Why Every Business Needs Professional Graphic Design Services

In today’s competitive marketplace, businesses rely heavily on visual communication to attract customers, build trust, and stand out from competitors. Whether you are a start-up or an established company, investing in professional graphic design services is essential for shaping how your audience perceives your brand. Great design is more than decoration; it is a strategic tool that influences customer decisions, communicates brand values, and creates memorable experiences.

This article explains why professional design is critical for every business and how it helps build strong branding, clear communication, and long-term customer loyalty.

The Power of Visual Branding in Modern Business

Branding is no longer limited to logos and color schemes. It includes the complete visual identity that customers associate with your business. This identity must be consistent across your website, social media, print materials, and physical signage. Professional graphic design services ensure that your branding is cohesive, modern, and aligned with your business goals.

Strong visual branding:

- Builds trust and credibility

- Enhances customer recognition

- Differentiates your business from competitors

- Creates emotional connections

- Supports long-term brand loyalty

When customers see professionally designed materials, they associate your business with quality and reliability.

Why Professional Graphic Design Services Matter

Many business owners try to use free online tools or templates for their design work. While these tools are helpful, they cannot replace the expertise of a trained designer. Professional designers understand color psychology, typography, layout balance, composition, and branding strategy. This knowledge allows them to create visuals that are not only attractive but also effective in communication.

1. Enhancing First Impressions

The first impression of your business often comes from your visuals. Whether it is a business card, website banner, brochure, or social media ad, your design plays a major role in shaping expectations. People decide within seconds whether they trust a brand, and design is at the center of this decision.

Professional graphic design services ensure that every touchpoint creates a positive first impression that encourages people to explore your business further.

2. Strengthening Brand Recognition

Customers remember brands through consistent visual cues. This includes your logo, fonts, colors, and layout style. A professional designer ensures that these elements work together seamlessly. Over time, this consistency improves brand recall and makes your business easily identifiable in a crowded marketplace.

This is especially important for businesses in industries with high competition. Well-designed branding becomes a strong differentiator.

3. Improving Communication with Your Audience

Effective visuals simplify complex messages. For example, infographics, diagrams, icons, and illustrated guides can help customers understand your products or services faster. Professional designers know how to structure information visually so it is engaging, simple, and persuasive.

Clear communication is essential in marketing. When your message is visually appealing, customers are more likely to take action, whether visiting your website, making a purchase, or contacting you for a service.

4. Supporting Marketing and Advertising Efforts

Marketing campaigns rely on strong visuals. From social media ads to promotional flyers, professional graphic design services help create materials that capture attention and drive engagement. A good design increases the chances of people clicking on your ad, reading your content, or responding to your call-to-action.

Bad design, on the other hand, can cause customers to scroll past your posts or ignore your promotions entirely. Design quality directly affects marketing results.

Investing in Professional Design Builds Customer Trust

Trust is a major factor in every customer’s purchasing decision. If your brand visuals look outdated, inconsistent, or unprofessional, customers may assume your products or services lack quality as well. Investing in professional design makes your business appear credible and reliable.

Good design demonstrates that your business cares about quality and pays attention to detail. This creates confidence and encourages customers to choose your brand over others.

How Custom Designs Elevate Your Brand Identity

Templates may be cheap and convenient, but they look generic. Custom designs reflect your unique story, mission, and personality. Professional designers take time to understand your brand, audience, and goals before creating visuals that represent you accurately.

This is where Custom graphic design solutions from Kwik Kopy become especially valuable. These services provide unique, tailored designs that help your brand stand out across digital and print channels.

Advantages of Custom Design

- Unique visuals that match your brand voice

- Better alignment with your target audience

- Adaptability across marketing materials

- Enhanced professionalism and brand appeal

- Stronger long-term brand consistency

Custom graphic design solutions from Kwik Kopy ensure that your brand communicates its message clearly and stands out against competitors who rely on generic templates.

How Graphic Design Influences Customer Decisions

Design plays a psychological role in how people interact with brands. The colors you use can trigger emotions. The layout of your website can influence whether visitors stay or leave. The professionalism of your printed materials can determine whether clients trust you.

Here are a few ways design affects customer behavior:

- Color choices influence mood and brand perception

- Typography impacts readability and tone

- Layout affects engagement and decision-making

- Visual hierarchy guides attention and improves message clarity

Every design choice affects how customers interpret your brand.

Examples of How Custom Printing Helps Brands Stand Out

Although this article focuses on design, printing plays a major role in brand presentation. Custom printing transforms digital designs into tangible brand assets.

Here are examples of how businesses use printing to make an impact:

- High-quality brochures with premium finishes build trust in professional services

- Branded packaging enhances customer experience and increases perceived product value

- Custom business cards leave a strong impression in networking events

- Printed banners and signage make brands more visible at trade shows

- Branded stationery reinforces identity in corporate communication

When combined with Custom graphic design solutions from Kwik Kopy, printed materials become powerful tools for marketing and customer engagement.

Why Every Business Size Benefits from Professional Design

Whether you run a small local shop or a large corporation, design influences how customers perceive you. Small businesses often gain the most from investing in quality design because it helps them appear more credible and compete with larger brands. Major companies, on the other hand, rely on graphic design services to maintain consistency across multiple platforms and campaigns.

Professional design scales with your business and adapts to your ongoing needs, ensuring your branding stays modern and competitive.

Conclusion

Professional graphic design services are essential for every business that wants to grow, build trust, and communicate effectively. High-quality visuals strengthen brand identity, improve customer engagement, and support marketing efforts. With expert designers, your brand gains a polished, consistent, and memorable appearance that attracts customers and sets you apart.

BUSINESS

How Long Do E-Cycle Batteries Last? Cycles, Depth of Discharge, Real Math

Electric cycles (e-cycles) have revolutionized commuting, recreation, and fitness by blending the simplicity of traditional bikes with the power of electric motors. However, one critical component often faces scrutiny from prospective and existing users: the battery. Understanding how long an e-cycle battery lasts is vital because it directly affects range, performance, lifespan, and ultimately, overall cost of ownership.

This article unpacks the science and math behind e-cycle battery longevity, focusing on charge cycles, depth of discharge, ageing factors, and practical care tips to help riders maximize battery life and get the most from their investment.

The Backbone: What Is an E-Cycle Battery?

Modern e-cycles predominantly use lithium-ion batteries, favored for their energy density, weight savings, and relative safety. These batteries consist of multiple cells arranged in series and parallel configurations to achieve the required voltage and capacity.

Battery capacity is measured in watt-hours (Wh), indicating how much energy it can store. Typical e-bike batteries range between 300 Wh to over 700 Wh. Higher capacity translates to longer rides but also impacts weight and cost.

What Is a Charge Cycle?

A charge cycle is a foundational concept in battery lifespan discussions. It refers to one full charge and discharge sequence, but not necessarily from 0% to 100% in one go. For example:

- Discharging from 100% to 50% and then recharging back to 100% counts as half a cycle.

- Draining to 25% and recharging to 75% also equals half a cycle.

E-cycle batteries are rated by their number of charge cycles before they degrade significantly, generally defined as dropping to 70%-80% of original capacity. Most lithium-ion e-bike batteries last between 500 to 1,500 full charge cycles, which translates to 3 to 5 years for average daily riders. Some quality batteries, with careful use, can stretch even beyond 1,000 cycles.

Depth of Discharge: Why Partial Charging Extends Battery Life

Depth of discharge (DoD) indicates how much of the battery’s capacity is used before it is recharged. The deeper the discharge (e.g., draining from 100% to 0%), the more strain placed on the battery cells.

Studies and manufacturer guidelines consistently show shallower discharges extend battery life:

- Frequently recharging at 50%-60% DoD can double the effective lifespan compared to full discharges.

- Partial charging and top-ups minimize stress on the battery chemistry.

Therefore, it is recommended to avoid full battery depletion and frequent overnight charging to 100%. Maintaining the battery charge between approximately 20% and 80% is optimal for long-term health. This practice smoothens voltage swings and slows the chemical degradation inside lithium-ion cells.

Real Math: Estimating Battery Lifetime

Let’s do a real-world calculation to understand how cycles and DoD influence battery lifespan, using an e-cycle battery rated for 1,000 full cycles and a capacity of 500 Wh:

- Full cycle capacity = 500 Wh × 1,000 cycles = 500,000 Wh total energy throughput.

If you often practice partial charges, say averaging 50% DoD per recharge, each partial charge counts as 0.5 cycles, meaning you get roughly twice the number of cycles (2,000 charge events) before reaching the equivalent full cycle degradation.

In simple terms:

- At 100% DoD (full cycles), you get 1,000 cycles.

- At 50% DoD, you can get approximately 2,000 charging sessions.

If your average daily ride consumes 250 Wh, the battery provides two full charges per day based on 500 Wh capacity. In this case:

- 1,000 full cycles = 1,000 × 250 Wh/day usage = 250,000 Wh total energy delivered over the battery lifetime.

- Multiply by the daily energy use to estimate lifespan in days, then convert to years.

Assuming daily usage and charging habits aligned with 50% DoD, your battery could last over 5 years before capacity falls below 70-80%, the point when performance noticeably declines.

Ageing Factors Beyond Charge Cycles

While cycles are crucial, batteries also degrade over calendar time and usage conditions that impact chemical stability:

- Temperature: Exposure to extreme heat accelerates aging by increasing internal cell resistance and chemical breakdown. Cold reduces immediate capacity temporarily but can affect performance less long-term. Store batteries in cool, dry places.

- Storage State: Storing batteries fully charged or fully depleted for prolonged periods causes faster degradation. Manufacturers advise storing batteries at 30-60% charge levels if unused for weeks or months.

- Load and Usage: Frequent high-power output, rapid discharge, or very steep climbs put extra stress on the battery and shorten lifespan. Moderate, steady use conserves battery health.

- Charging Quality: Using manufacturer-recommended chargers, avoiding overcharging, and preventing deep discharges preserve battery chemistry.

- Physical Damage: Impact, water ingress, or improper mounting can cause internal cell damage, shortening battery life abruptly.

Signs Your Battery Needs Replacement

Batteries wear gradually, but some symptoms indicate when replacement is needed:

- Reduced range and runtime.

- Longer charging times or failure to fully charge.

- Noticeable voltage fluctuations causing inconsistent motor power.

- Physical signs like swelling, leakage, or corrosion.

Replacing the battery when capacity falls below about 70% restores performance and extends the life of your e-cycle without buying a full new bike.

Practical Tips to Maximize Battery Life

Apart from riding and charging practices, here are user-level tips to ensure the longevity of your e-cycle battery:

- Avoid letting the battery completely drain before recharging.

- Prefer partial charges and top up often.

- Remove the battery from the bike when storing or charging indoors.

- Protect from extreme climates and store in stable environments.

- Use only compatible chargers and avoid cheap knock-offs.

- Schedule regular maintenance and inspect for physical wear or damage.

- Pay attention to battery management system (BMS) alerts or error codes.

Battery Technology Innovations Extending Lifespan

Battery manufacturers continually improve lithium-ion chemistry and design:

- Advances in solid-state batteries promise higher cycle counts and safer operation.

- Improved BMS algorithms optimize charging curves and cell balancing.

- Enhanced thermal management in battery packs prevents overheating.

These innovations mean future e-cycle batteries will have longer lives, faster charging, and even better reliability, pushing e-cycles further into sustainability and cost-effectiveness.

Final Thoughts

Understanding the real math behind e-cycle battery lifespan empowers riders to make informed choices about their e-bikes, how to use them, and when to replace components. While typical lithium-ion batteries last 3 to 5 years or 500 to 1,500 charge cycles, smart charging habits and maintenance can significantly extend that window.

By keeping the battery’s depth of discharge moderate and protecting it from temperature extremes, the life of the battery—and the enjoyment and utility of the e-cycle—can be maximized, making electric cycling an even more compelling and economical option in personal transportation.

-

GENERAL2 years ago

GENERAL2 years agoDiscovering the Artistic Brilliance of Derpixon: A Deep Dive into their Animation and Illustration

-

Posts2 years ago

Posts2 years agoSiegel, Cooper & Co.

-

HEALTH2 years ago

HEALTH2 years agoTransformative Health Solutions: Unveiling the Breakthroughs of 10x Health

-

Lifestyle2 years ago

Lifestyle2 years agoPurenudism.com: Unveiling the Beauty of Naturist Lifestyle

-

FASHION2 years ago

FASHION2 years agoThe Many Faces of “λιβαισ”: A Comprehensive Guide to its Symbolism in Different Cultures

-

Lifestyle2 years ago

Lifestyle2 years agoBaddieHub: Unleashing Confidence and Style in the Ultimate Gathering Spot for the Baddie Lifestyle

-

Entertainment2 years ago

Entertainment2 years agoGeekzilla Podcast: Navigating the World of Pop Culture, Gaming, and Tech

-

Lifestyle1 year ago

Lifestyle1 year agoSandra orlow: Unraveling the Story of an Iconic Figure